Aquatec In depth – Monitoring Sediment Processes for Hydropower Applications

Suspended sediment concentration is an important parameter to be monitored in all three varieties of hydropower stations – run of river, reservoir and pumped storage. When a hydropower facility is constructed and in operation, the natural flow of the river is changed, leading to significant alterations in sediment processes. This can substantially affect the water environment upstream and downstream.

Instrumentation

The AQUAscat 1000 range is a series of high frequency acoustic profilers designed to observe suspended sediment concentration and mean grain size within a water body. The instrument is most suitable for particle sizes between 20 μm and 500 μm radius and concentrations of 0.01 g/l to 20 g/l over 1 m, or more over a shorter range. Most AQUAscat instruments have integrated temperature and depth sensors to provide operators with a better understanding of the water environment. Some instruments have the option to integrate a turbidity sensor to provide a separate single point measurement of turbidity, giving optical measurements as well as acoustic.

The AQUAscat 1000 range provides valuable knowledge on the sediment processes taking place. This can be done at a single location to produce a time series or via transects to observe spatial variability. The instruments can observe profiles of <1 m to 10 m (depending on the model), to provide information on the sediment processes close to the bed or in the water column. The AQUAscat is the ideal instrument for measuring suspended sediment concentration (SSC) and mean grain size in hydropower facilities, as it is non-intrusive and suitable for long-term, unattended deployments, allowing operators to respond to sediment fluctuations when necessary.

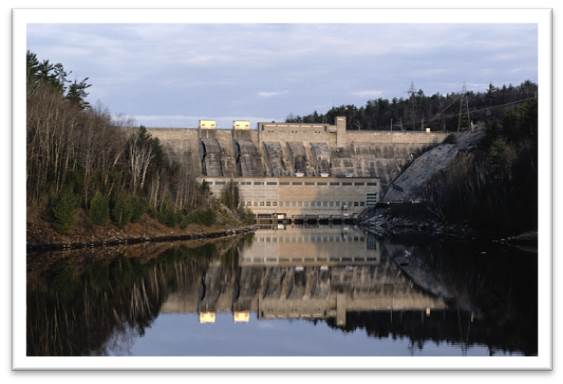

Deposition in a Reservoir

Water in a reservoir is less mobile than water in rivers, therefore when a reservoir is constructed, the amount of deposited sediment increases. This can result in a rise in water level. On some occasions, this issue can further lead to flooding or failure of a dam. Therefore monitoring the sediment processes during the operation of hydropower stations can be crucial. When sediment levels exceed a certain capacity, the removal of sediments is required. Information on sediment processes within hydropower stations can assist in flood management upstream and river basin management downstream, and allow industry professionals to respond accordingly.

During monsoon season or in the event of a storm, some hydropower plants can be particularly vulnerable to increases of sediment. On some occasions, when the sediment load exceeds a particular capacity and is considered a danger to the structure, flushing of the dam takes place to remove the built up sediment. This is done to prevent clogging. The AQUAscat can be deployed at sensitive locations during these events to measure the fluctuations of sediment load.

Sediment flushing has further implications downstream, as it can affect the structure of the hydropower station and the aquatic ecosystem. During the process of flushing, sediment levels escalate within the water downstream. This area, which has already been deprived of sediment deposition taking place due to the construction of the hydropower facility, becomes exposed to very high levels of sediment. This process can substantially affect the aquatic ecosystem by destroyed habitats and distressing aquatic organisms. In extreme cases, flushing can result in high mortality rates of organisms. It is crucial that this process is monitored to prevent or reduce these impacts. Using the AQUAscat, operators can monitor the sediment levels during the process and therefore control the concentration of sediment being flushed.

Downstream Erosion

Hydropower stations can cause an accumulation of sediment within a reservoir, which can result in environmental implications downstream. The river flow would naturally transport and deposit the sediment downstream. However, in an area where a reservoir has been constructed, the sediment is blocked from travelling downstream. The water released is sediment deficient and often has more energy. This can result in increased erosion of the river bed and riverbank. Hydropower operators can benefit from monitoring the sediment processes taking place downstream to get a better understanding of the environmental impacts. Increased erosion rates can affect local communities occupying floodplain areas. Greater knowledge of the rates of erosion can benefit communities that might be at risk.

Impact on Turbines

Depending on the sediment properties and the flow of sediment, features of the hydropower plant itself can be affected. Sediment can damage turbines, bottom outlets, valves and gateways. During the operation of run-of-river and pumped storage facilities, the hydraulic turbines are often at risk of sediment abrasion and erosion. This is particularly the case in events of heavy rainfall where the turbines are exposed to large amounts of sediment. As the sediment particles pass through the turbines with the flow of the water, the turbines are subjected to abrasion from hard particles, causing erosional wear of the turbine material. This can reduce the productivity and operational lifetime of the turbines. The extent of erosion depends on the particle properties, sediment concentration and the speed of water flow. Hard particles such as granite and sand are likely to cause more erosional wear than soft materials like silt and mud. Similarly, the larger the sediment particle, the more it will damage the turbines. Fixing or replacing hydraulic turbines is very expensive, which is why monitoring the sediment processes taking place in run-of-river and pumped storage stations is extremely important.

Using the AQUAscat, hydropower professionals can gain a better understanding of the sediment processes. This information can indicate the degree of damage taking effect on the turbines. The AQUAscat can provide information over a long period of time, which is useful for analysing sediment trends. With enhanced knowledge, operators can be prepared to respond to dangerous levels of sediment. They can assess when the turbines will need fixing or replacing, or take action to prevent any long term damage to turbines and thus reduce operational expenditure.

References

Espa, P., Castelli, E., Crosa, G. and Gentilli, G. (2013). Environmental Effects of Storage Preservation Practices: Controlled Flushing of Fine Sediment from a Small Hydropower Reservoir. Environ¬mental Management, Volume 52, Issue 1, pp. 261-276.

Gray, L, J. and Ward, J, V. (1982). Effects of sediment releases from a reservoir on stream macroinvertebrates. Hydrobiologia 96, pp. 177-184. Available at: http://www.ephemeroptera-ga-lactica.com/pubs/pub_g/pubgrayl1982p177.pdf [Accessed 20 June. 2016].

Padhy, M, K. and Saini, R, P. (2008). A review on silt erosion in hy¬dro turbines. Renewable and Sustainable Energy Reviews, Vol¬ume 12, Issue 7, pp. 1974-1987.

Thapa, B., Shrestha, R., Dhakal, P. and Thapa,, B. S. (2005). Sedi¬ment in Nepalese Hydropower Projects. Journal of Aquatic Eco¬system Health and Management, Volume 8(3), pp 251-258.

Find out more

For more information on the AQUAscat range of instruments, click here.