The Aquatec Group designs and manufactures leak detection systems for the oil industry, with over 15 years experience. We use a variety of detection techniques, including fluorescence detection, active and passive acoustic detection, thermal gradient detection, and pressure differential systems. Aquatec leak detection systems are field-proven and have been used on projects around the world. We also provide systems and operator personnel for hire across the globe, as well as on-site and remote training.

Key features

- ROV or diver held • Field proven systems • Two stage detection process

- 3 different types of sensors • Long range fluorometers with max range of 10m • Acoustic sensors for when dye is not permitted

- Complete systems including sensors, data acquisition system and Toughbook PC

Rental Kit

The Aquatec leak detection rental kit is supplied as a complete system, with the following components:

- LEAKlog 2-channel data acquisition system rated to 3500 m

- RS232/485 converter

- 24V power cable tail for ROV Communications cable tail for ROV

- Toughbook PC with pre-loaded AQUAtalk control and display software

- 1 or 2 Leak detection sensors, selected from:

- Long Range Rhodamine/Roemex 9022 Fluorometer sensor LEAKlog LR-FR

- Long Range Fluorescein Fluorometer sensor LEAKlog LR-FF

- Long Range UV Fluorometer sensor LEAKlog LR-UV

- Fast response thermal sensor LEAKlog T1

- Passive acoustic sensor LEAKlog T1

Why rent with Aquatec?

- A proven range of instruments and services for offshore applications.

- Competitively priced rental rates so you can reduce the expenditure on your project.

- Technical support and training is available.

- Short and long term rental rates.

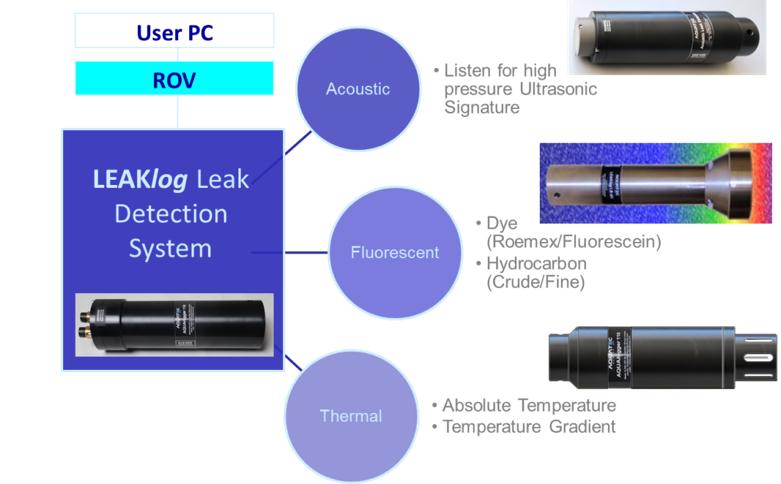

The LEAKlog System

DATA ACQUISITION

Aquatec’s leak detection systems use our tried and tested AQUAlogger data acquisition technology, also found in hydrotest data loggers and our oceanographic data logging instrumentation. The standard LEAKlog acquisition system has two independent channels that may be connected to a range of different sensors. AQUAtalk software on the user’s PC allows real-time display of leak detection signals

FLUORESCENCE DETECTION

During precommissioning, fluorescent dye may be injected into the pipeline during the flooding phase so that any leaks are more easily detected. Fluorescent dyes are also used in control fluids. Models in our LEAKlog LR series of long range fluorometer sensors are available for various fluorescent tracers, including ultra-violet sensors, which are also able to detect hydrocarbons. The sensors can detect very small quantities of tracer dye resulting from leaks, even in highly turbid conditions, when traditional ‘black light’ technology is insufficiently sensitive. The maximum detection range of a significant leak in clear water is greater than 10 metres.

ACOUSTIC LEAK DETECTION

Following research into the typical signals emitted by high pressure leaks, a highly sensitive directional ultrasonic detection sensor was developed. Background noise such as from an ROV, is filtered out, so that only the ultrasonic signals in the band of interest are monitored and analysed. The LEAKlog PA1 acoustic sensor operates alongside the existing fluorometer or thermal sensors, thus providing a two-stage detection process. It is also ideal for situations where the use of fluorescent dyes is either unfeasible or not permissible.

THERMAL LEAK DETECTION

When there is a temperature differential between the sea water and the contents of a pipeline, the fast response LEAKlog T1 temperature probe can be used to detect small thermal plumes rising from the leak source. The probe can provide an absolute temperature output, or an ultra-sensitive temperature gradient output. Typical differential temperature sensitivity is in the order of millidegrees.