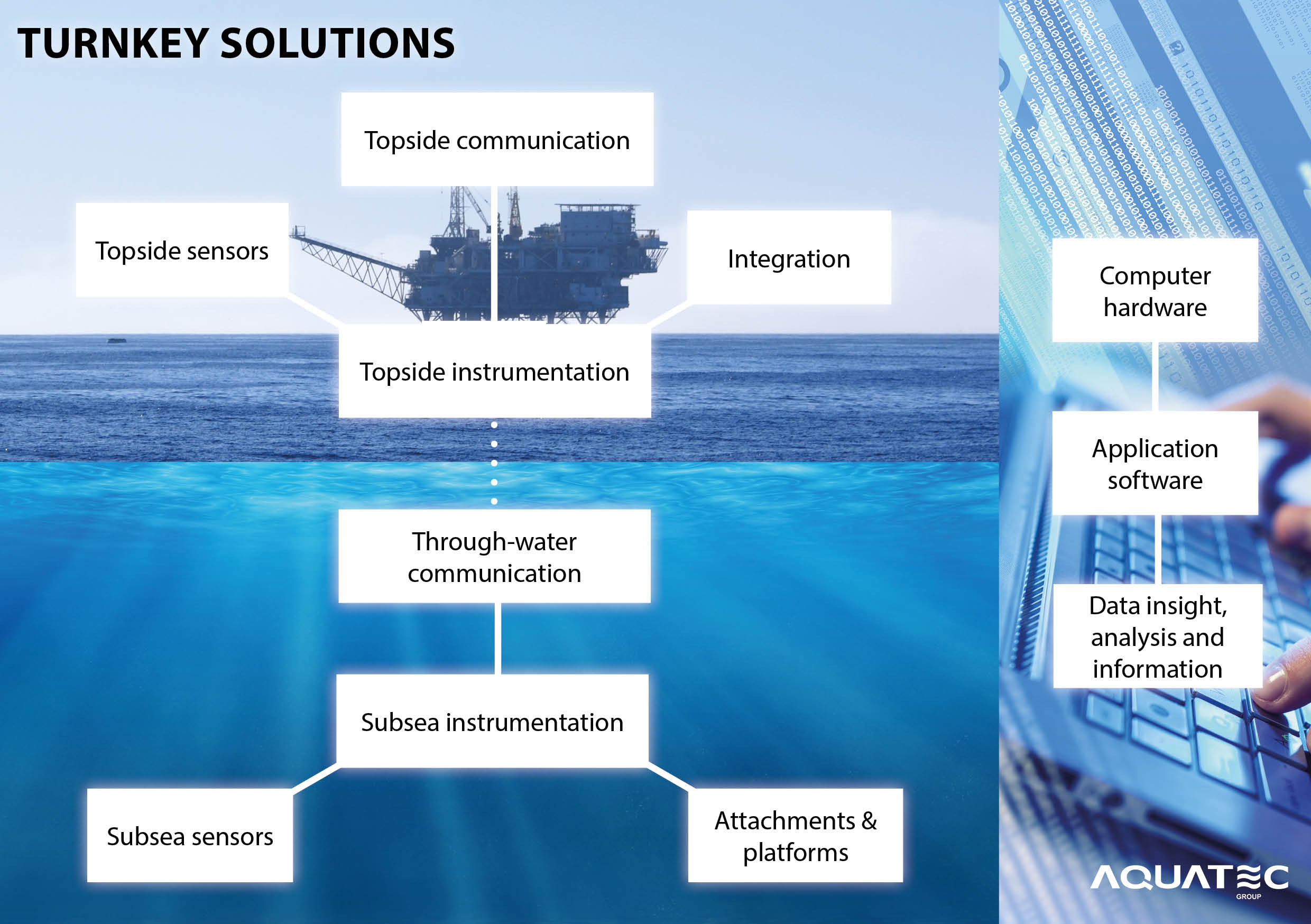

Aquatec’s strength lies in our ability to produce custom engineered solutions to diverse subsea measurement and communication problems.

Using the core Aquatec technologies of logging, acoustics and subsea communication, and the design capabilities of our in-house engineering team, we design and supply complete turnkey solutions to meet a wide range of subsea measurement and communication requirements.

Aquatec have extensive experience in this area and have been solving our clients’ problems with innovative solutions for over 25 years, utilising the latest technology and leading design and manufacturing techniques.

Through communication and consultation, we work with you to find the optimum solution to meet your project needs, selecting our own instrumentation when design cycles need to be rapid, and integrating instruments from many third party providers where appropriate. In-house technologies such as data loggers, displays, acoustic modems, optical modems, switches, and clamps provide the building blocks for our bespoke systems. Additional services such as feasibility studies are available where needed, for brand new ideas or proof of concept projects

Click on the headings below to find out more.

Designing, delivering and supporting the turnkey solutions are the Aquatec Solutions Team – a group of experienced engineers who work with you to meet your project requirements. With decades of combined experience, the team have designed new instruments, modems and systems for customers all over the world in the variety of different industries.

In house expertise includes: oceanographic instrumentation, low power data loggers, digital signal processing, underwater acoustic communication, temperature and pressure measurement, corrosion and cathodic protection, pressure vessel design, underwater optical instrumentation and high frequency acoustics.

Sensors - subsea and topside

Subsea instrumentation

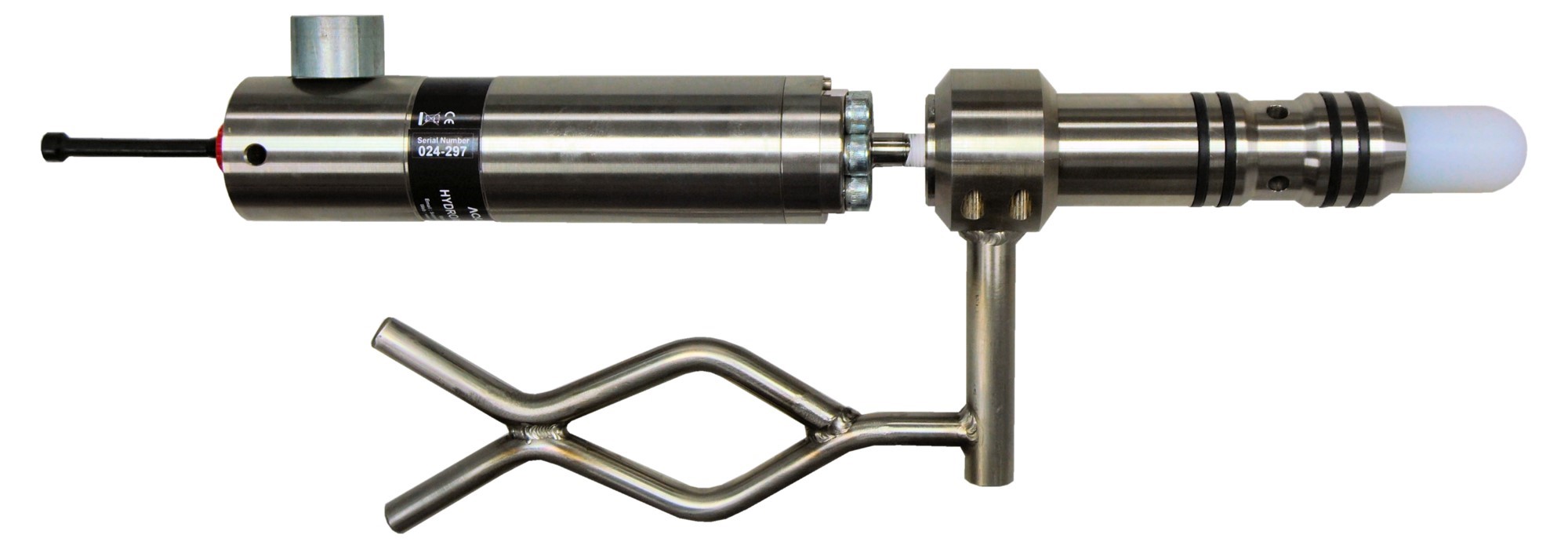

Aquatec have wide-ranging experience in subsea instrumentation design, including the range of data loggers with integrated sensors available as standard products. In 2017, we launched the next generation logging platform in the form of the AQUAlogger 310 and HYDROlog 3000 series instruments.

Aquatec loggers have built-in logging capability, as well as the option for real time data transfer where needed. It is possible to interface to a wide variety of sensors, including 4-20mA, 0-5V, 0-10V, RS422, and RS232. As well as utilising standard products, loggers can be customised or new instruments designed, using the in-house PCB and housing design capabilities. Aquatec has experience designing housings for depths of up to 6000m, including integrated anodes for corrosion protection.

Features such as flexibility of deployment and variable sampling regimes are standard in the next generation logging platform. User-friendly features such as quick start with a magnet and status LEDs can be incorporated where required.

Instruments are powered internally with a range of battery options, or externally powered via a mains supply or battery packs. Custom battery pack design is available if a long battery life is needed (e.g. 10-15yr) or high frequency sampling is required.

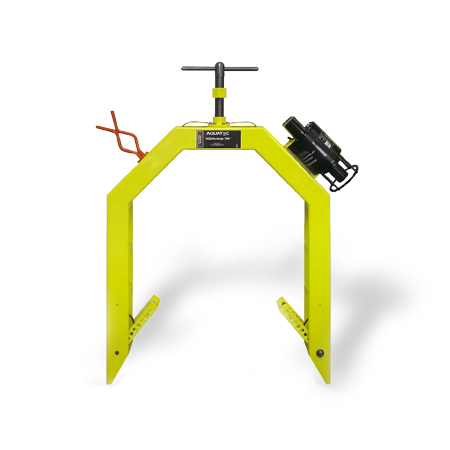

Attachments and platforms

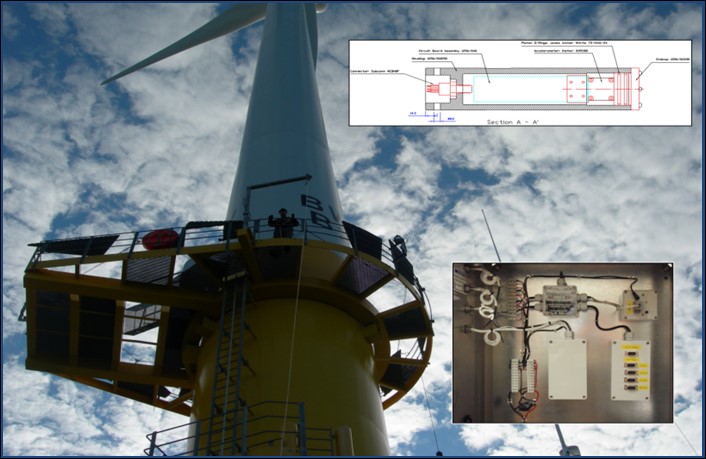

Sensors, instrumentation and modems for data transfer need to be deployed and mounted in position underwater. Aquatec provide a variety of different options, depending on the application.

The AQUAclamp is a retrofit clamp that allows instrumentation to be deployed on pipelines and structures. In addition, Aquatec has experience designing custom clamps for individual sensors (such as the transducer clamp for the AQUAscat) and mooring lines.

The addition of ROV handles and ROV bars makes deployed by ROV easy. Instrumentation has even been mounted on hot stabs. Packages for the payload bays of AUVs can also be developed.

For autonomous and long term deployments, subsurface or surface buoys can be fitted out with equipment (see below). Aquatec also designs skids and manifolds for in-house and third party instrumentation.

We also design custom fittings for specialised applications, such as the pipeline temperature monitoring system below.

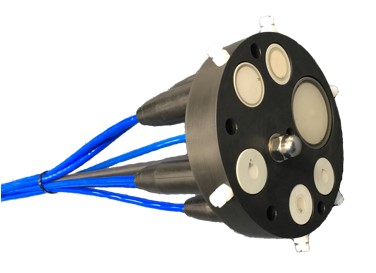

Through-water communication

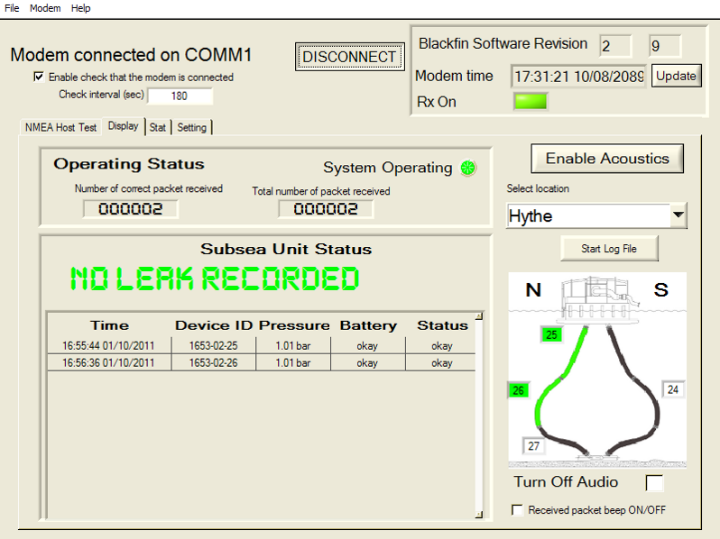

For some systems, subsea cables are used to connect instruments to a point at the surface or subsea hub/modem for onward data transfer. Where cabled solutions are unsuitable, due to the distances involved, hydrodynamics or location-specific restrictions, wireless through-water communication is considered. Aquatec first launched a subsea communication system in 1997 - the first acoustic AQUAmodem. Since then, we have developed four AQUAmodem technologies – an optical modem system (AQUAmodem Op2) and three acoustic modems (AQUAmodem S500, 500 and 1000). In addition to our core technologies, we can integrate a range of other communication methods, including radio modems.

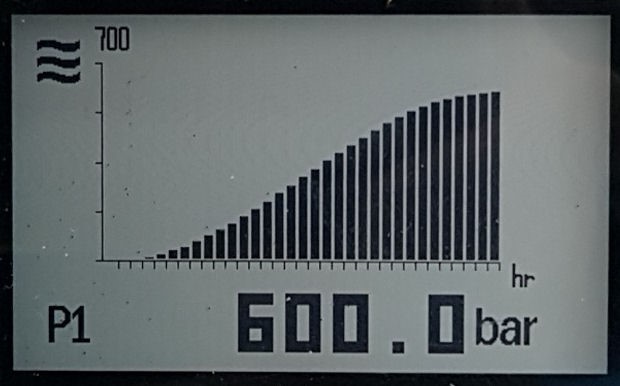

As a complementary technology to underwater data transfer, subsea displays enable a visual check of subsea instruments and observation of real time data, via divers and ROVs. Aquatec’s AQUAdisp digital display can be added as a standalone component or integrated into an instrument or system. The AQUAdisp monitors up to 16 parameters and displays the data over 4 screens in either a numerical or graphical format.

Topside instrumentation

In combination with or as an alternative to subsea instrumentation, topside instruments can be incorporated if needed to store data or transfer information to modems or computer hardware.

Topside communication

Once the data has reached the surface, it then needs to be transferred to the required location. This may be achieved using cables for short distances or via wireless through-air communication methods such as radio, mobile network or satellite. The suitability of each method is assessed at the proposal stage, and a topside communication solution designed accordingly.

Integration

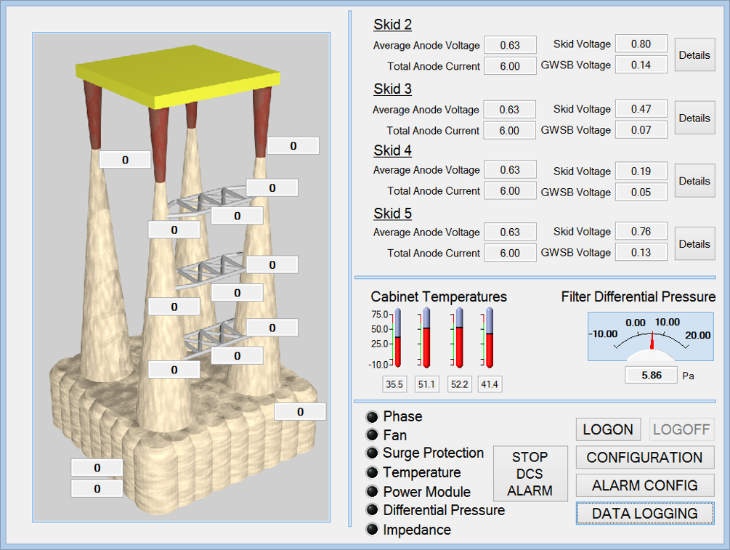

Aquatec’s turnkey solutions can be integrated into wider systems in a number of ways. Data from Aquatec instrumentation can be integrated into existing computer hardware, or to remote and distributed systems. Components of the systems can be physical integrated into existing structures, such as manifolds and skids, as well as subsea and topside equipment being designed for specific locations.

Computer hardware

If required for the application, Aquatec can provide standalone PCs with pre-loaded software or provide software for existing hardware. Integrated tablets and screens are also an option.

Application software

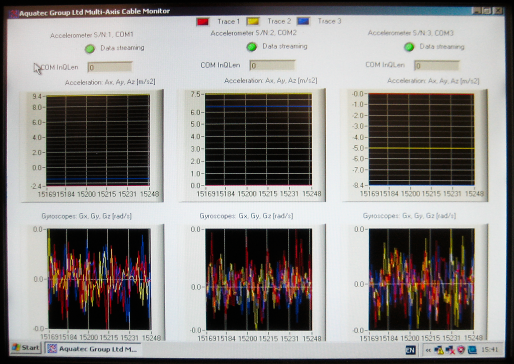

A critical part of any system is the user interface, allowing instruments to be instructed, settings modified, and data viewed and downloaded. At Aquatec, application software is customised to meet your needs, using our in-house software AQUAtalk an d modifying where necessary. Data and information can be displayed in a number of ways, including numerically, on graphs and using diagrams.

Data insight, analysis and information

As well as providing data and information via the application software, Aquatec can also provide data access on a secure website (to permit remote access) and reporting/analysis services to help you understand your data. Experienced Aquatec personnel can monitor system health checks, download logged data or review real time data, and generate a report in which the data is analysed. As the designers, suppliers and installers of the systems, Aquatec experts are ideally placed to offer insight into ongoing system operation. As the reports include an analysis of the data, benefits include optimisation of the system, reduction in waste and early identification of potential issues. The scope of analysis and report is tailored to your project, agreed in advance. Additional consultancy services and recommendations based upon data retrieval, interpretation and analysis are available.